1. Drill Overview

- Time: 16:40-17:30 on January 17, 2026

- Venue: Factory basketball court

- Participants: All employees of Lab Companion

- Objective: Consolidate the enterprise's safe production defense line, enhance employees' fire safety awareness and emergency response capabilities

2. Pre-Drill Preparation (16:00 onwards)

- The General Department prepared all necessary drill tools in advance.

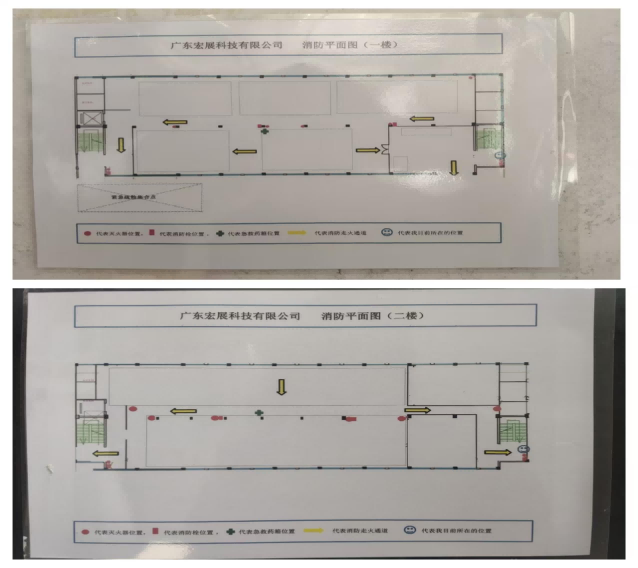

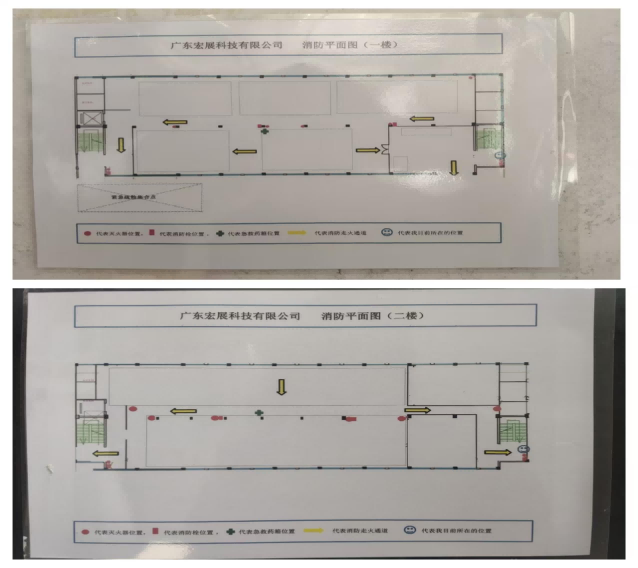

- Conducted a comprehensive inspection of the integrity of on-site fire-fighting facilities (including fire extinguishers and hydrants).

- Verified the clarity and accuracy of emergency route maps to ensure all emergency resources were in optimal standby condition.

3. Emergency Evacuation Process

- 16:35: Team leaders took positions promptly and notified employees at each workstation to prepare for emergency assembly, ensuring no information omission or delay.

- 16:37: The fire alarm was activated on time, and the entire factory entered an "emergency state".

- Guided by team leaders, employees evacuated along fire escape routes (bending down, covering mouths and noses) to the assembly point.

- All employees completed safe assembly within 3 minutes; the General Department supervisor conducted a head count to confirm no one was left behind.

4. Core Training & Practical Operations

Centered on the theme of "Prevention First, Life First", the safety and security supervisor delivered on-site training:

- Explained key fire prevention points and initial fire-fighting skills combined with typical cases.

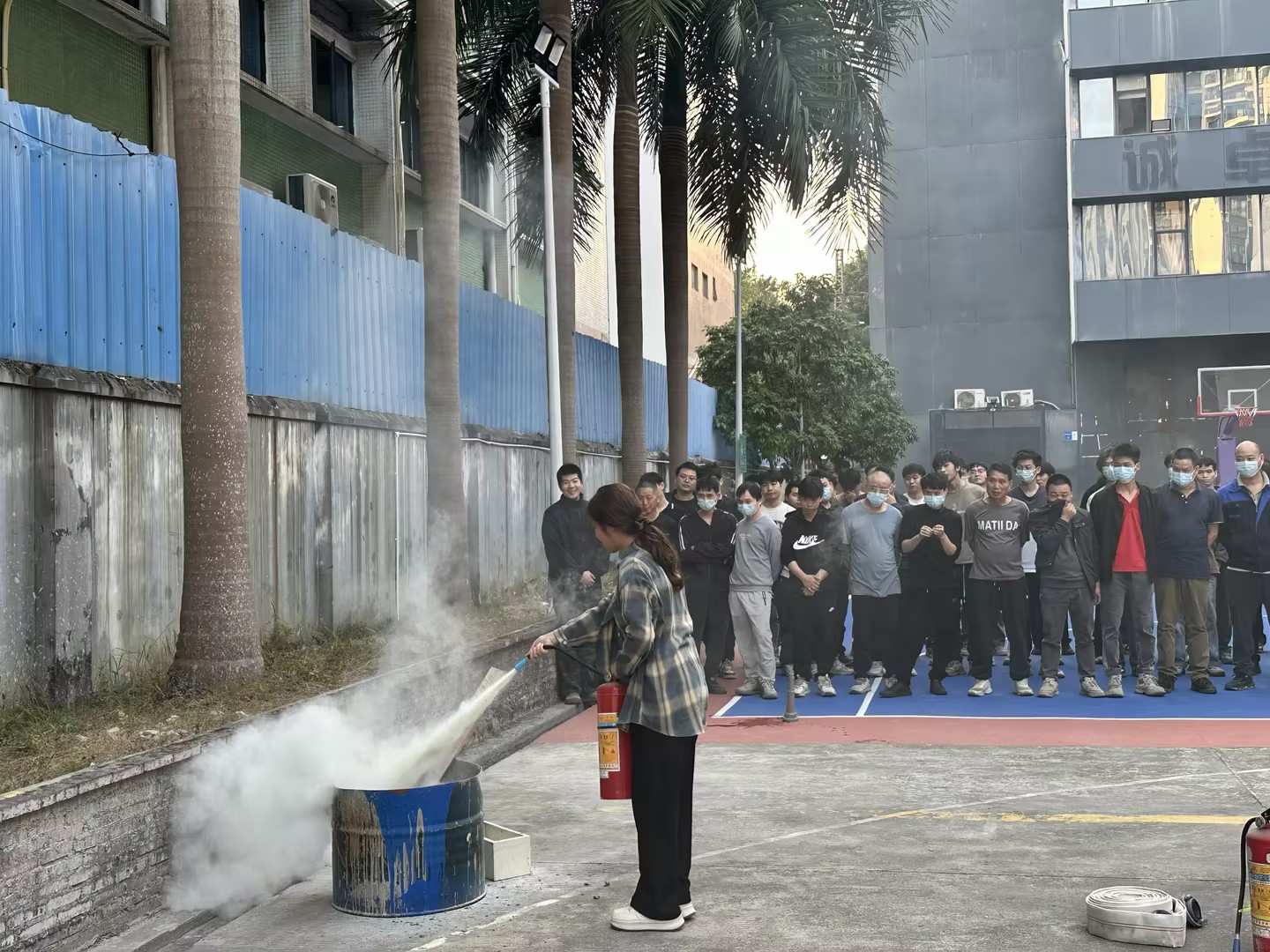

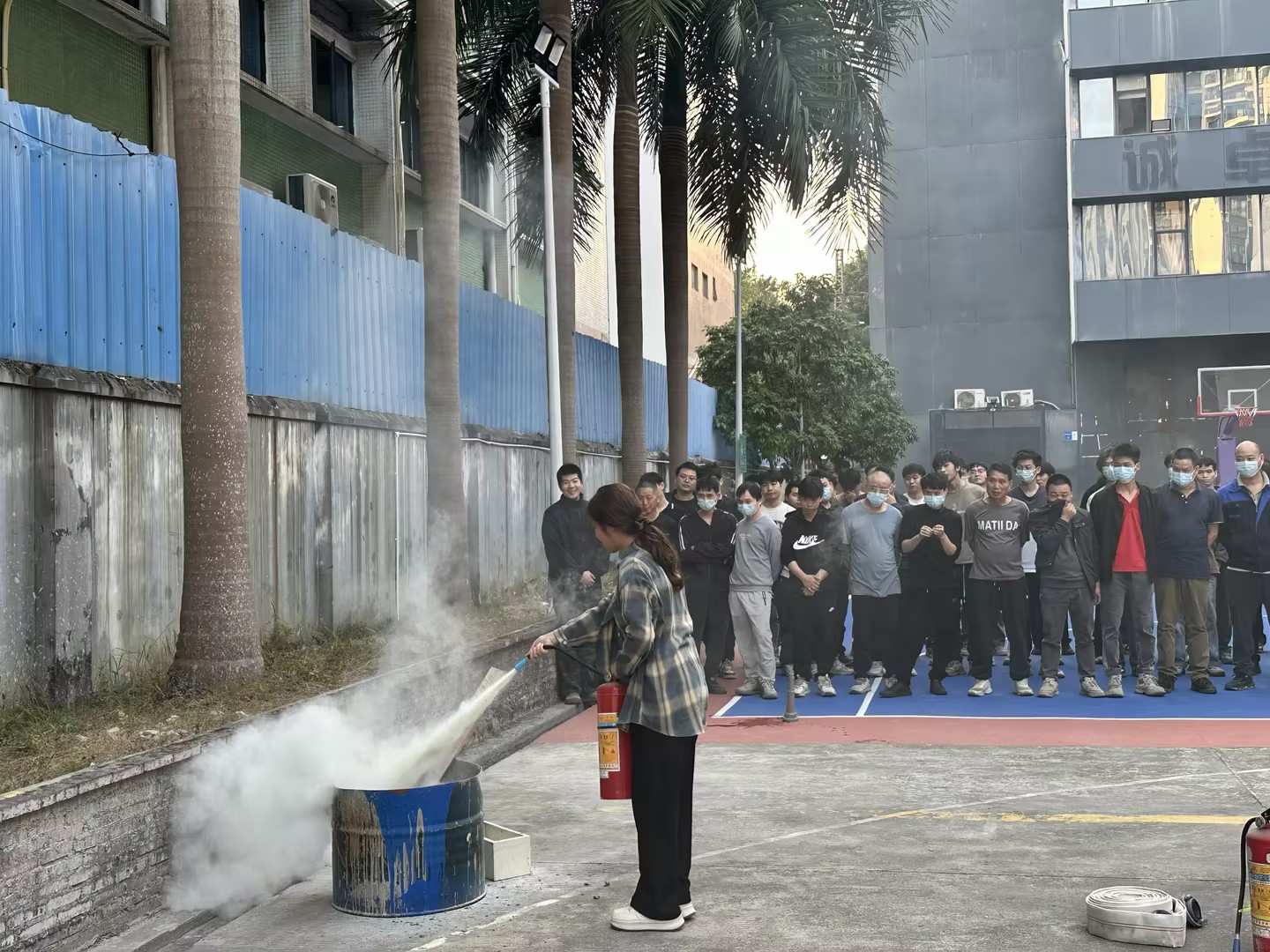

- Demonstrated the four-step fire extinguisher operation ("lift, pull, hold, squeeze") and rapid fire hose connection techniques.

- Organized random employees to practice oil pan fire extinguishing, achieving "integration of teaching and practice, everyone passing the test".

- Targeted the company's production characteristics to demonstrate the chemical leakage emergency response process (covering risk identification, protective measures, leak control, and post-disposal).

5. Drill Achievements

- The drill was well-organized, with standardized processes and substantial content.

- Effectively tested the practicality and operability of the company's fire emergency plan.

- Polished the collaborative linkage mechanism between departments.

- Enhanced employees' fire-fighting skills and safety awareness in a realistic scenario.

- Fulfilled the expected goals of "testing the plan, polishing the mechanism, training the team, and popularizing science and education".

6. Follow-Up Plans

- Take this drill as an important starting point to deepen safe production management.

- Promote the construction of a dual prevention mechanism for risk classification control and hidden danger investigation.

- Integrate fire safety work into daily operations.

- Conduct regular emergency drills and strengthen safety knowledge publicity and education.

- Continuously improve the enterprise's emergency management level to safeguard high-quality development.